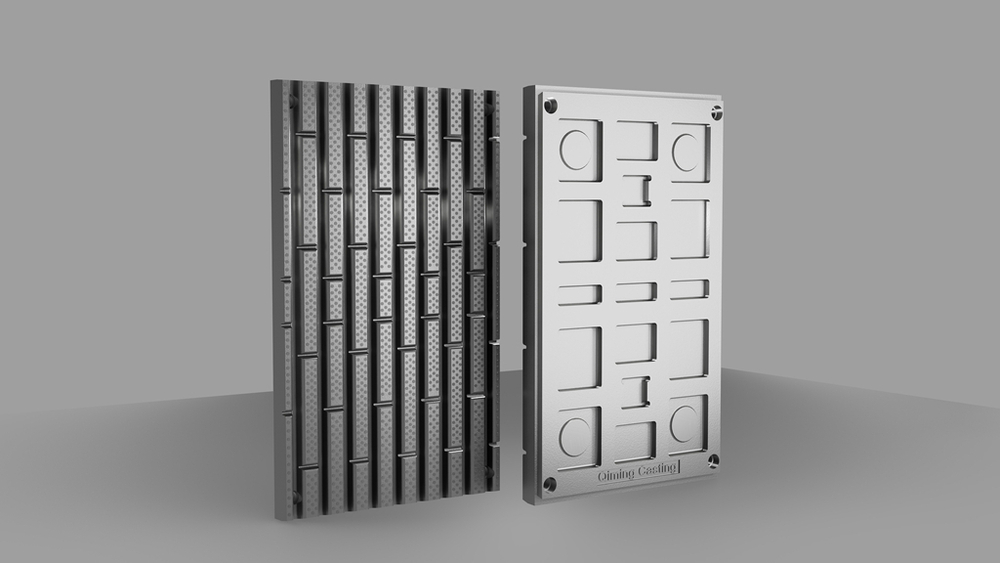

Jaw Crusher Plate

MOQ : 50 Pieces

Jaw Crusher Plate Specification

- Size

- Custom (fit for small, medium, and large jaw crushers)

- Product Name

- Jaw Crusher Plate

- Steel Type

- Stainless Steel

- Surface

- Shot Blasting / Hardening / Heat Treatment / Anti-Wear Coating / Machined Finish

- Color

- Metallic Grey / Black / Custom Anti-Rust Coating

Jaw Crusher Plate Trade Information

- Minimum Order Quantity

- 50 Pieces

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 500 Pieces Per Month

- Delivery Time

- 10 Days

About Jaw Crusher Plate

Unlock exclusive durability and exceptional performance with our Jaw Crusher Plate, engineered for unrivaled efficiency in demanding environments. Available at India's lowest price, this prime offer features customized sizing to seamlessly integrate with small, medium, and large jaw crushers. Benefit from resplendent surfaces including shot blasting, hardening, heat treatment, anti-wear coating, or a machined finish, crafted from superior stainless steel. Choose from metallic grey, black, or custom anti-rust coatings-directly from a leading manufacturer and supplier. Experience long-lasting strength and unmatched reliability, only with our Jaw Crusher Plate.

Jaw Crusher Plate: Applications & Surface Integration

Our Jaw Crusher Plate demonstrates robust performance at crushing sites, ranging from mining to construction applications. Whether installed at aggregate plants or mineral processing facilities, its tailored surface treatments-such as shot blasting and anti-wear coating-deliver optimal wear resistance. Designed for direct contact with abrasive materials, the plate's advanced finish guarantees prolonged service life and enhances productivity in prime site operations, ensuring consistent output where durability is essential.

Supply Capacity & Sample Availability for Jaw Crusher Plate

Delivered promptly after order completion, our Jaw Crusher Plate supply ability ensures timely arrival for every client. Manufacturers and suppliers in India offer flexible sample options, supporting quick evaluation before purchase. Samples come under a favorable sample policy to meet diverse needs, providing confidence in quality and compatibility. Assured supply for all crusher sizes guarantees fast fulfillment from the moment your order is confirmed, contributing to smoother operational planning and reduced downtime.

Jaw Crusher Plate: Applications & Surface Integration

Our Jaw Crusher Plate demonstrates robust performance at crushing sites, ranging from mining to construction applications. Whether installed at aggregate plants or mineral processing facilities, its tailored surface treatments-such as shot blasting and anti-wear coating-deliver optimal wear resistance. Designed for direct contact with abrasive materials, the plate's advanced finish guarantees prolonged service life and enhances productivity in prime site operations, ensuring consistent output where durability is essential.

Supply Capacity & Sample Availability for Jaw Crusher Plate

Delivered promptly after order completion, our Jaw Crusher Plate supply ability ensures timely arrival for every client. Manufacturers and suppliers in India offer flexible sample options, supporting quick evaluation before purchase. Samples come under a favorable sample policy to meet diverse needs, providing confidence in quality and compatibility. Assured supply for all crusher sizes guarantees fast fulfillment from the moment your order is confirmed, contributing to smoother operational planning and reduced downtime.

FAQ's of Jaw Crusher Plate:

Q: How is the Jaw Crusher Plate customized for various crusher sizes?

A: Jaw Crusher Plates are precisely manufactured to custom specifications, accommodating small, medium, and large jaw crusher models for seamless installation and optimal performance.Q: What surface treatments are available for the Jaw Crusher Plate?

A: We offer a variety of surface treatments including shot blasting, hardening, heat treatment, anti-wear coating, and machined finish, each enhancing wear resistance and durability in harsh crushing environments.Q: When can samples of the Jaw Crusher Plate be delivered to customers?

A: Samples are typically delivered promptly after order completion, governed by a favorable sample policy that facilitates swift evaluation before finalizing a purchase decision.Q: Where is the Jaw Crusher Plate ideally used?

A: The Jaw Crusher Plate is ideally used in mining and construction sites, aggregate plants, and mineral processing facilities where robust crushing performance and surface resilience are required.Q: What benefits does the anti-rust coating offer on the Jaw Crusher Plate?

A: Our custom anti-rust coating effectively protects the plate against corrosion, ensuring extended operational life and reducing maintenance needs when exposed to moisture or chemical-laden environments.Q: How does the manufacturer ensure rapid supply of the Jaw Crusher Plate?

A: With proven supply capacity, the manufacturer ensures orders are fulfilled quickly, facilitating timely arrival and reducing downtime for diverse crushing plant operations across India.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Steel Harding Plate Category

Cheek Plate

Minimum Order Quantity : 50 Pieces

Surface : ShotBlasted / Machined / HeatTreated for Wear Resistance

Steel Type : Stainless Steel

Grade : Mn13 / Mn18 / Mn22 / Alloy Steel Grades

Product Name : Other

Composition : High Manganese / Alloy Elements as per grade specification

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS